Quality Forming

High-Quality in the Cold Forming Process

Since 1991, QF has specialized in the production of Fittings and special parts for the Automotive brake system by Cold Extrusion and Cold wire forming into rods. QF's production focuses on the international Automotive sector and recently also on the motorcycle and mining sector.

QF produces parts according to Customer's Drawing, thereby satisfying specific needs with complete efficiency and quality. For this reason all products are in full compliance with the specifications and performance requirements.

Technology

Nowadays, QF is the leader in Metal Cold Forming Sector, providing with maximum Quality of the produced components at highly competitive prices.

High Quality

QF’s fundamental mission is the attention to the highest quality at every stage of the production process and that of the finished product.

Research and Development

The internal Research and Development laboratory enables QF to identify the most appropriate solutions for each specific Customer request, while combining functionality, innovation and timeliness.

Certifications

QF is certified ISO 9001 and IATF 16949 certified, guaranteeing quality and safety of both production processes both finished product offered on the market

Quality Forming

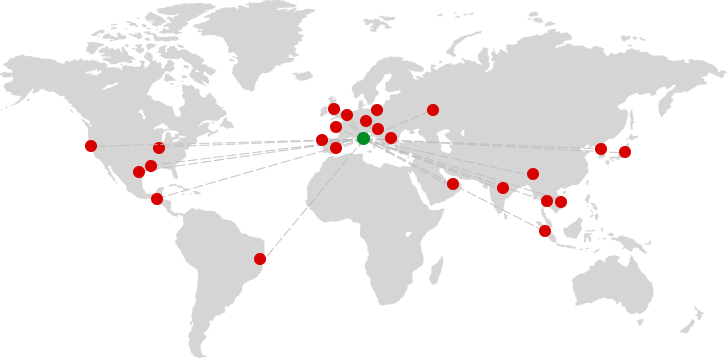

in the World

Thanks to the high production flexibility and the proven Quality of its products, QF has been able to establish important partnerships with countries all over the world.

Currently, QF supplies the most prestigious European companies in the Automotive Sector

Since 30 years Leader in Cold Forming

QF, established in 1991, is proud to celebrate together with you its 25 years of specialization in production of special parts in accordance with client design, guaranteeing minimal expense for maximum quality.

The latest product range is on-line

To learn more about our product range, register and browse a sample of our automotive and mining product range. Quality and safety are guaranteed.